NOWOFLON ET Release Film for high-temperature applications

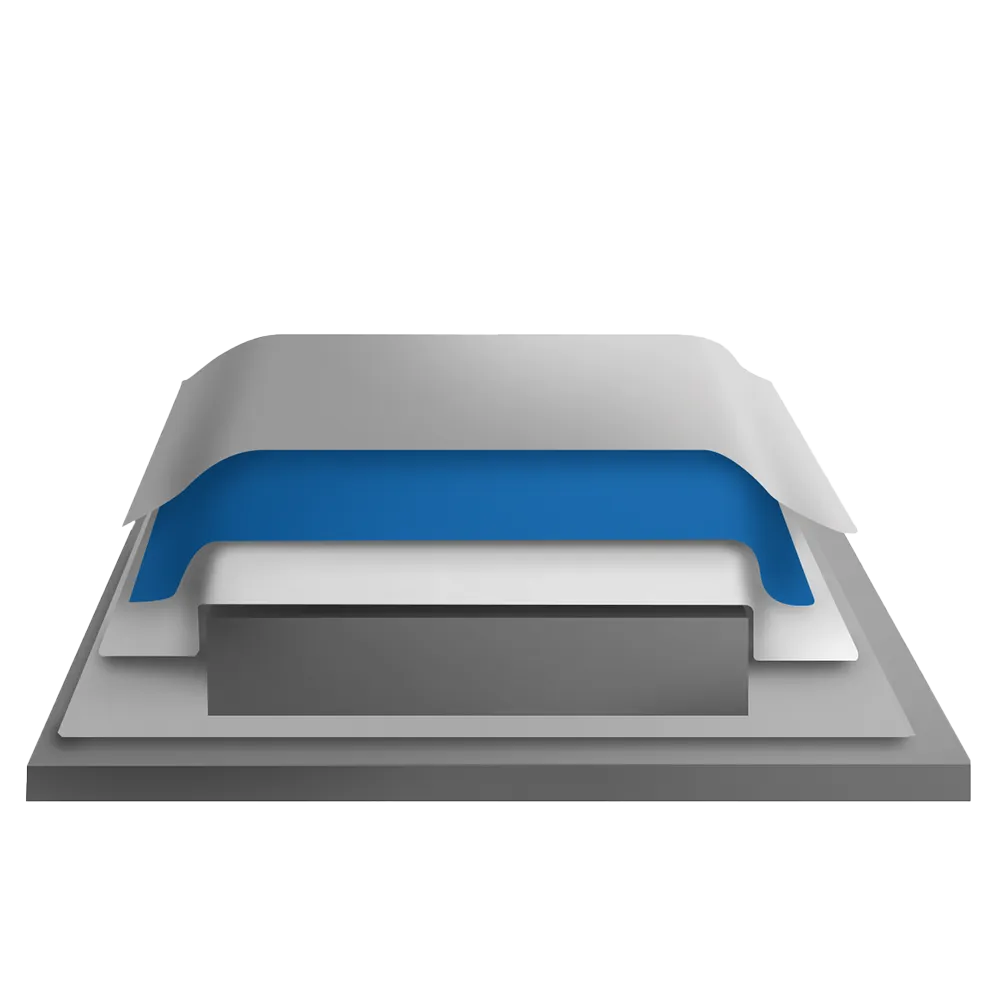

With the ETFE release film NOWOFLON ET, NOWOFOL has created an extremely temperature-resistant, robust release film for use in industrial environments.

Excellent release properties, high elongation at break and excellent stability at high processing temperatures make the fluoropolymer film NOWOFLON ET a reliable release film in the production of glass fiber reinforced (GRP) and carbon fiber reinforced (CFRP) components in the automotive and aerospace industries. The ETFE release film NOWOFLON ET is also used in semiconductor production.

Applications

ETFE release film for GRP and CFRP component production, as well as a release film for semiconductor production.

Thickness

12, 15, 20, 25, and 100 µm (0.4, 0.6, 0.8, 1 and 4 mil)

Colours

Available in Blue (12-25 µm / 0.4-1 mil),

red (15-20 µm / 0.6-0.8 mil),

white (100 µm / 4 mil)

Widths

1.300, 1.500 and 1550 mm (51, 59 and 61 inch)

Design/Perforation

Type 1: without perforation / smooth

Type 2: Hole perforation: 5 mm (0.2 inch) distance, hole Ø approx. 0.7 mm (0.01 inch), Index HN400

+ Robust and reliable

NOWOFLON ET release film provides film properties that are essential for outdoor applications:

- High tear and tear propagation resistance

- Excellent peel performance

- Excellent surface adhesion

- Suitable for all common resin systems

- Continuous operating temperature 150 ° C / Shorttime (6-8 hours) up to 230 ° C

- Certified according to DAN5089B0

Fluoropolymer films for extreme conditions. ETFE solutions that resist heat and chemicals

Andreas Freutsmiedl, Head of Sales Fluorpolymer Films

+ Your Product Request